Menu

Leading infrared technology.

Made in Austria.

Where WMT is written on it, there is innovation inside. Find out here what makes our technology unique.

We will be happy to answer any questions you may have.

The drying process with the DryPanel®

A dry affair? Yes, at least as far as the result is concerned. The exciting physical processes set in motion by the DryPanel® are extremely effective.

This is how it works

- The DryPanel® heats the air space between the board and the masonry as well as the wall surface with the generated infrared C radiation.

- The accumulated warm air absorbs moisture and rises through the vents. Cooler and dry air is drawn in from below.

- The resulting circulation allows the masonry to dry continuously.

- With greater wall thicknesses, a pressure effect is created in addition to the suction effect. As moisture moves away from warm zones, it is also released into the room air on the opposite wall surface. The infrared radiation can even heat through wall thicknesses of 50 cm and above.

The FlatPanel® technology.

Optimum efficiency

Our claim is to develop infrared technologies with optimum efficiency. With FlatPanel® technology, we have succeeded in ensuring maximum radiation with minimum energy consumption.

Less is more. Much more.

Thanks to innovative surface heating technology, live wires or heating coils in the board are no longer necessary. Infrared C radiation with uniform radiation of approx. 85 °C is generated directly on the heating board.

Targeted radiation instead of heating the entire room

Reflectors focus the infrared radiation specifically at the point to be dried in the masonry. In this way, you achieve a maximum radiation effect with low input powers of 210 to 500 watts.

Leaner. More effective. More comfortable.

FlatPanel® technology is convincing all along the line: with an extremely thin structure of only 2 mm, impressive radiation efficiency and even more convenient use in everyday work.

Unique in the world.

Our WMT engineers have developed the FlatPanel® technology in cooperation with renowned research laboratories. The technology is unique in the world.

Even more efficient: Interval drying with the DryPanel® ZI

Now save an additional 35 % energy during construction drying. The new DryPanel® ZI is equipped with a counter and an interval circuit and enables regular heating and cooling. The capillary effect creates a suction that pulls the moisture from the inside of the wall to the surface without active energy supply.

Data and facts

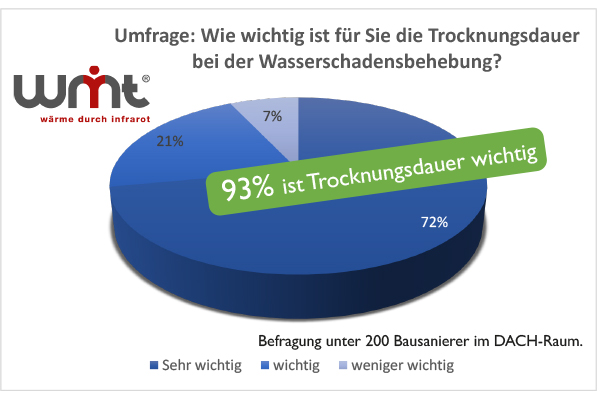

Building renovators agree: the drying time is what counts.

A survey of 200 building renovators in German-speaking countries has shown that drying time is an enormously important factor in damage repair.

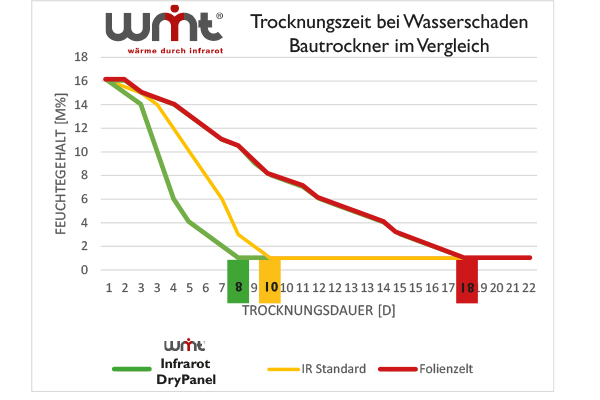

The DryPanel® keeps the best time.

In comparison with classic infrared devices and foil tents, the DryPanel® clearly asserted itself as the fastest solution for repairing water damage.

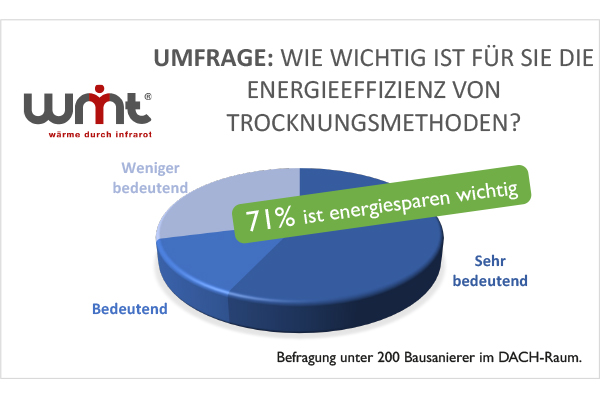

Building renovators are placing more and more emphasis on energy-efficient drying solutions.

Saving energy is an important need in building renovation - this was confirmed by a survey of 200 companies.

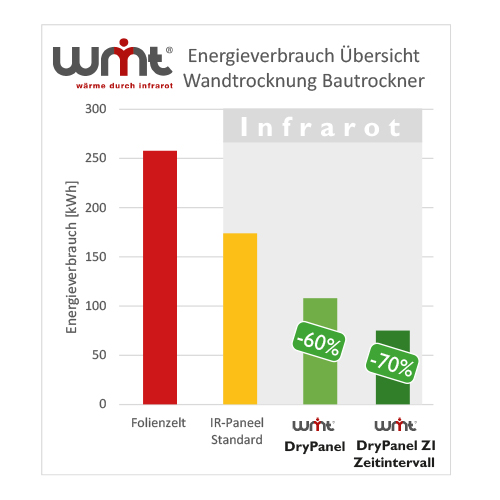

The DryPanel® is energy saving master.

When comparing the energy consumption of different devices for wall drying, the DryPanel® clearly prevailed as the most efficient solution.